In the modern textile industry, silicone oil for textile finishing plays an indispensable role as an important chemical auxiliary. It not only significantly improves the performance and quality of textiles but also meets consumers’ demands for comfortable, aesthetically pleasing, and durable textile products. Let’s delve deeper into the various roles of silicone oil in textiles.

What is Silicone Oil?

Silicone oil, also known as polysiloxane, is a type of organosilicon compound with a main chain composed of silicon-oxygen bonds and organic groups attached to silicon atoms. Silicone oil possesses many unique physical and chemical properties, such as low surface tension, good lubricity, heat resistance, cold resistance, weather resistance, and chemical stability. As a key component in silicone finishing for textiles, it plays a pivotal role in improving fabric performance and quality.

Silicone Oil for Textiles: Softening and Smoothing Effects

(I) Principle

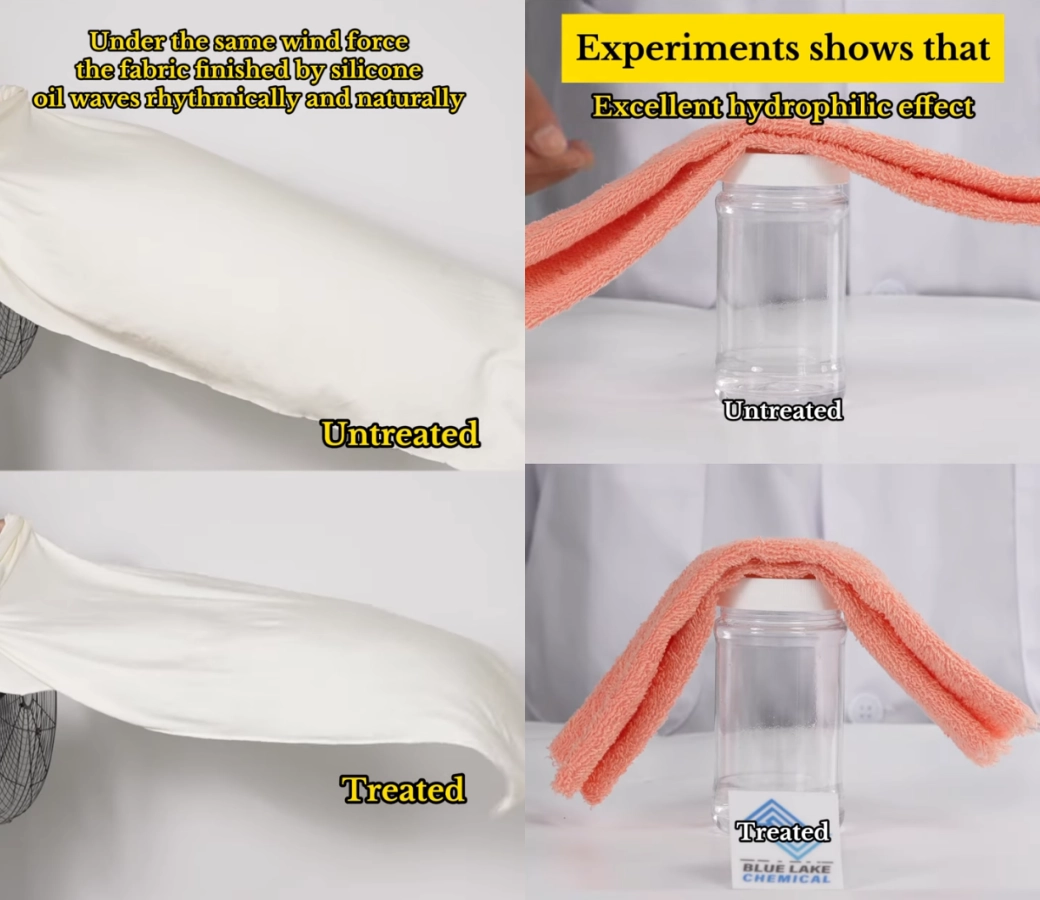

Silicone oil can significantly improve the softness and smoothness of textiles. Silicone oil molecules can form a uniform lubricating film on the fiber surface, effectively reducing the friction coefficient and mutual resistance between fibers, making the fabric softer and smoother to the touch.

(II) Practical application examples

Untreated cotton fabrics often feel rough and lack elasticity. Adding silicone softener during the printing and dyeing process can make these fabrics softer and more flexible, improving the comfort when wearing. Similarly, high-end textiles such as silk and wool also benefit from silicone softener. For silk, silicone oil can enhance its softness and glossiness; for wool, silicone oil can prevent felting and improve dimensional stability.

Silicone Oil for Textiles: Enhancing Wrinkle Resistance

(I) Principle

Silicone oil can increase the elasticity and resilience of fibers and reduce the permanent deformation of fibers when subjected to external forces. Silicone molecules penetrate fibers and form chemical bonds or physical entanglements with fiber molecules, enhancing structural stability and elasticity.

(II) Practical application examples

In shirt fabrics, finishing with silicone oil can improve wrinkle resistance. It can remain flat even after multiple washes, reducing the need for ironing. Similarly, in some textiles that need to maintain a good appearance, such as curtains and bedding, after being treated with silicone oil, the occurrence of wrinkles can be effectively reduced, extending the service life and aesthetics of textiles.

Silicone Oil Finishing for Waterproofing

(I) Principle

Hydrophobic silicone oil forms a low surface film on the surface of the fabric, making it waterproof. When water droplets contact the surface of the fabric, it is difficult to penetrate, and the water droplets instead form water beads and roll off.

(II) Practical application examples

Outdoor clothing (such as sportswear) relies heavily on textiles coated with silicone oil to protect against rain. Silicone oil treatment ensures that the fabric remains breathable while providing excellent waterproof performance. In addition, specialized products such as waterproof tents and rain gear also use silicone oil to enhance durability and waterproofness in extreme conditions.

Silicone Oil for Textiles: Improving Wear Resistance

(I) Principle

Silicone oil can form a lubricating film to reduce friction and wear between fibers. This minimizes heat generation and wear during repeated friction, extending the service life of textiles.

(II) Practical application

Industrial workwear and backpack fabrics are often subjected to great friction. Treating these materials with silicone oil improves wear resistance, ensuring that they can withstand frequent friction and pulling without being easily damaged. The properties of silicone oil make it an ideal choice for textiles that need to enhance durability and life.

Silicone Oil Finishing for Gloss Enhancement

(I) Principle

Silicone oil can fill the tiny flaws and bumps on the fiber surface, making the fiber surface smoother and flatter. At the same time, the silicone oil molecules themselves have a certain refractive index, which can reflect light and make the textiles appear brighter.

(II) Practical application examples

Silicone softeners are widely used in high-end fabrics such as silk and chemical fibers. Evening dresses made of silk treated with silicone present a luxurious luster, while chemical fiber fabrics gain a refined and high-end appearance. The use of silicone oil in these textiles can enhance their aesthetic value and commercial value.

Other Benefits of Silicone Oil for Textiles

(I) Antistatic properties

Silicone oil can reduce the surface resistance of textiles, minimize the generation and accumulation of static electricity, and thus prevent static electricity from absorbing dust and causing discomfort when wearing and using textiles.

(II) Antibacterial properties

Some specially formulated silicone oils have certain antibacterial properties, which can inhibit the growth of bacteria and fungi on the surface of textiles and keep textiles clean and hygienic.

(III) Improve dyeing properties

Silicone oil can improve the permeability and uniformity of dyes on fibers, enhance dyeing effects, and make colors more vivid and lasting.

Precautions for Using Silicone Oil in Textiles

(I) Dosage control

Excessive use of silicone oil softener may cause greasy texture or reduced breathability. Appropriate dosage ensures optimal performance.

(II) Processing technology

Different textiles and processing requirements require the selection of appropriate silicone oil varieties and processing technologies. For example, different printing and dyeing processes such as dip dyeing and pad dyeing have different silicone oil addition methods and processing conditions.

(III) Environmental protection and safety

When choosing silicone oil, it is necessary to consider its environmental protection and safety. Some silicone oils that do not meet environmental protection standards may cause potential harm to the environment and human health.

In Conclusion

Silicone oil has many important functions in textiles, including softness and smoothness, wrinkle resistance, water repellency, wear resistance, and gloss enhancement. By using silicone oil properly, the performance and quality of textiles can be significantly improved to meet various industry needs. However, in the process of using silicone oil, attention should be paid to dosage control, selection of processing technology, and environmental safety issues to ensure that the application of silicone oil achieves the best results while meeting relevant standards and requirements.

As a leading silicone oil manufacturer, we provide innovative solutions for the textile industry. Whether you need silicone fluids to soften textiles, repel water or enhance shine, our line of silicone fluids offers unmatched performance and value.