Fixing Agent Textile Chemicals For Polyester, Nylon and blends

Fixing agent, used for polyester cotton, nylon, nylon cotton fabrics and other chemical fibers and their blended fabrics, has an excellent effect on the water fastness of chemical fiber foam

মডেল নং22307

টেক্সটাইল কেমিক্যালস ম্যানুফ্যাকচারার থেকে

টেক্সটাইল কেমিক্যাল সার্টিফিকেট

Product Description of Color Fixing Agent

22307 is mainly composed of polyamine polymer.

In the setting process for polyester/ cotton fabrics, it can react with hydroxide radical on cotton fibers and have autoreaction to crosslink to form a film, which can decrease the influence on fastness by sublimation of disperse dyes and improve the soaping color fastness and steam ironing color fastness.

It is suitable for polyester/cotton fabrics, which can decrease the influence on fastness after setting.

Features & Benefits

- Contains no formaldehyde, APEO or heavy metal ions. Fits environmental protection requirements.

- Has certain inhibiting effect on sublimation of disperse dyes in setting process, especially dyes of bright red, black and blue.

- Not influences the hand feeling or color shade of fabrics.

- Reduces one time middle setting. Shortens process.

- Easy for using. Can be used together with silicone oil in same bath in setting machine.

Typical Properties

| Appearance: | Light yellow liquid |

| Ionicity: | Cationic |

| pH value: | 6.5±1.0 (1% aqueous solution) |

| Solubility: | Soluble in water |

Instruction

Padding process:

Reference dosage of 22307: 10~40 g/L

Reference dosage of softener: X g/L

Dipping and padding (Pickup: 70~100%) → Drying and setting (130~160℃)

Application Example

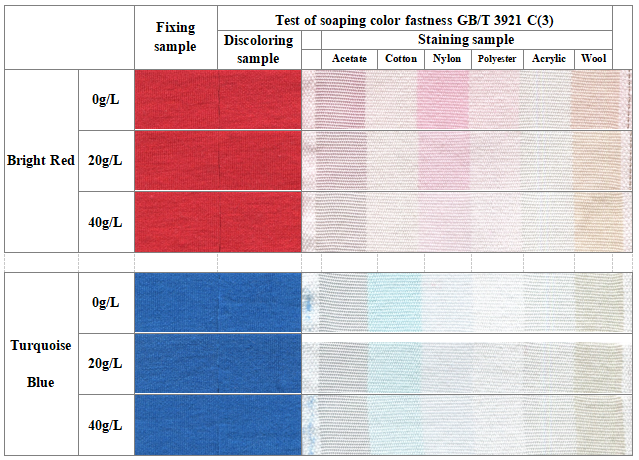

For improving fastness of double-sided fabric of 50/50 polyester/cotton:

(1)Dyeing polyester: 25℃ → 130℃×40 min (2℃/min) → Water washing

Bright red:

Disperse dye of bright red GS: 1.5%, High temperature leveling agent: 1 g/L, Acetic acid: 0.5 g/L

Turquoise blue:

Disperse dye of turquoise blue SGL: 1.5%, High temperature leveling agent: 1 g/L, Acetic acid: 0.5 g/L

(2)Reduction clearing:

Sodium hydrosulfite: 3 g/L

Caustic soda: 2 g/L

80℃×15 min (2℃/min) → Water washing

(3)Dyeing cotton: 25℃ → 60℃×60 min (2℃/min) → Water washing

Turquoise blue:

Reactive dye of turquoise blue BGFN: 1.5%, Reactive dye of brilliant blue KN-R: 1%,

Anhydrous sodium sulphate: 60 g/L, Caustic soda: 20 g/L

Bright red:

Reactive dye of bright red 3BS: 2%, Reactive dye of yellow 3RS: 1%,

Anhydrous sodium sulphate: 60 g/L, Caustic soda: 20 g/L

(4)Soaping:

Non-foaming soaping agent: 2 g/L

95℃×20 min (2℃/ min) → Water washing

(5)Fixing:

Formaldehyde-free fixing agent: 1%

40℃×20 min → Drying

(6)Setting:

Fixing Agent 22307: 0, 20, 40 g/L

Dipping and padding → Setting (170℃×about 90s)