In textile dyeing, achieving consistent and vibrant colors on fabrics is essential to producing a high-quality product. However, in some synthetic fibers, such as polyester and nylon, this can present challenges during the dyeing process. This is where dye carriers come in handy. These powerful additives help ensure that the dye effectively penetrates the fiber and achieves an even color distribution, even at lower dyeing temperatures.

What is a dye carrier?

A dye carrier is a chemical compound that favors the penetration of dyes into synthetic fibers, particularly at low temperatures. Dye carriers are added to improve the affinity of the dye for the fiber, enabling better uniformity in color uptake. The improved dye penetration offered by dye carriers also enables dyeing of fabrics at lower temperatures, which is energy-saving and less detrimental to the fabric.

How do dye carriers work?

Dye carriers temporarily change the structure of the fiber to allow better dye absorption. They act as a solvent or co-solvent in the breaking down of dye particles to move freely within the fiber matrix. This ensures that the dye will penetrate deep into the fabric, rather than just sitting on the surface, which can result in uneven coloring.

The Main Functions of Dye Carriers:

- Improving dye penetration: Because of the reduction of surface tension provided by dye carriers, the dye molecules can deeply penetrate into fibers, which becomes quite important with synthetic fibers.

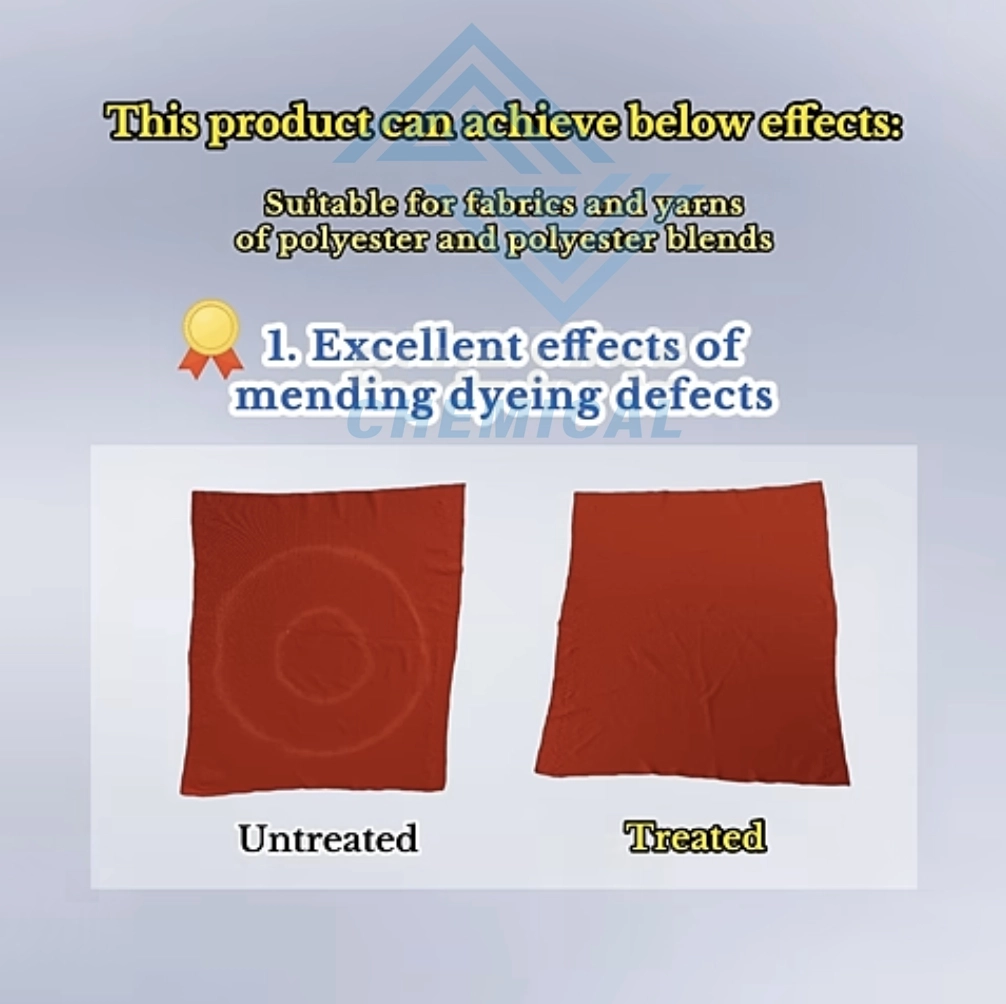

- Enhancing color uniformity: Dye carriers eliminate color spots or streaks in fabrics; their action allows homogeneous absorption of dyes, hence providing a uniform color.

- Reduction of dyeing temperature: Dye carriers allow the effective dyeing at lower temperatures, hence saving energy and avoiding damage to sensitive fabrics, especially delicate fibers.

- Improving dye fastness: Proper dye penetration ensures that the dye is well bonded to the fiber, hence improving color fastness.

Applications of Dye Carriers in the Textile Industry

Dye carriers have been found useful in dyeing synthetic fibers such as polyester, nylon, acrylic, blends. Synthetic fibers are difficult to dye due to low water absorption. Dye carriers enable dyeing at lower temperature which enables better dye penetration to ensure that synthetic fibers are well dyed without affecting the natural fibers.

Choosing a Dye Carrier that Suits Your Needs

When choosing a dye carrier for your textile dyeing process, many factors come into play:

- Type of fabric: The type of fiber you are dyeing will determine the choice of dye carrier. Polyester, nylon, and acrylic fibers require different carriers than cotton or wool.

- Dyeing Conditions: Consider such conditions as temperature and time. Dye carriers are in a position where one needs to lower the temperature or shorten the time of dyeing.

- Environmental Impact: Consider the impact of the material on the environment; hence, look for those that are iron-friendly and emit no hazardous fumes or waste during the dyeing process.

- Cost-Effective: Select a dye carrier that balances the performance to cost ratio to achieve optimal results without overspending on unnecessary chemicals.

Conclusion

Dye carriers are indispensable in ensuring effectiveness in your dyeing process and also in developing excellent quality, specifically in synthetic fibers. They enhance dye penetrative ability, homogeneous color, and lower dyeing temperatures-a method that ultimately will make your dyeing economical with less energy use.

At BLUELAKECHEM, we specialize in high-performance dye carriers and other textile auxiliaries designed to optimize your dyeing process. Our products help you achieve vibrant, consistent colors and high-quality textiles that meet market demands. If you are looking for innovative solutions to improve your dyeing process, or have any questions about our products, please feel free to contact us for a consultation. We are here to help you take your textile manufacturing process to the next level!