In textile manufacturing, achieving vibrant, even, and long-lasting colors is essential to producing high-quality fabrics. However, the dyeing process is complex and prone to problems such as uneven color distribution, poor dye penetration, and fabric damage. To address these challenges, textile manufacturers rely on a range of dyeing auxiliary chemicals that increase the effectiveness of dyes and improve the overall dyeing process.

In this article, we’ll explore the top five dyeing auxiliaries every textile manufacturer should know and how they contribute to a smoother, more efficient dyeing process.

Sequester

What it is:

A sequester, also known as a sequestering agent, is a compound that binds to metal ions (such as calcium and magnesium) present in water or dye baths. These metal ions can interfere with the dyeing process, and the sequester effectively “traps” the metal ions, preventing them from reacting with the dye or fiber. This helps maintain the dye bath’s stability and prevents precipitating formation, which would otherwise cause streaks or spots on the fabric.

Why it is essential:

Sequestering agents prevent metal ion interference, ensuring more even dyeing and improving the color intensity of the final product, especially when using hard water with high calcium and magnesium content.

Anti-wrinkle agents

What it is:

Anti-wrinkle agents are chemicals used to reduce or eliminate creases or wrinkles formed during the dyeing or finishing process, especially in delicate fabrics. Anti-wrinkle agents work by changing the molecular structure of the fabric, relaxing the fibers and reducing the formation of wrinkles during the dyeing process. They also help fabrics maintain a smooth and flat appearance after dyeing, preventing unwanted marks or creases.

Why it is essential:

Anti-wrinkle agents are particularly useful when dyeing sensitive fabrics such as silk, wool, and cotton. They ensure that these fibers remain smooth and wrinkle-free throughout the process, which is essential to producing high-quality, beautiful-looking textiles.

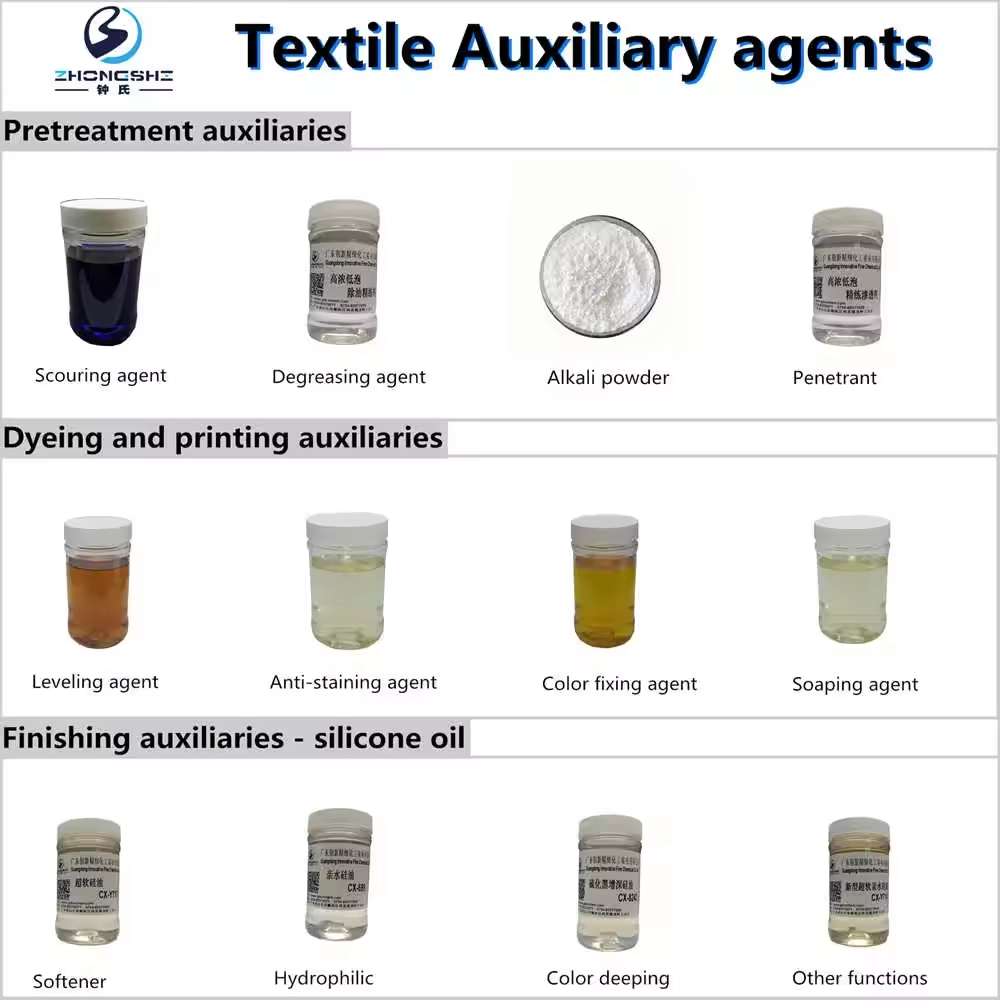

Dispersants and leveling agent

What they are:

Dispersants and leveling agents are essential auxiliaries used to ensure that the dye is evenly distributed on the fabric during the dyeing process. Dispersants break up dye aggregates into smaller particles, increasing their solubility and ensuring that the dye is evenly distributed throughout the dye bath. Leveling agents control the absorption of dyes into fabrics, promoting even coloring without unevenness or spotting.

Why they are essential:

Dispersants and leveling agents are essential to achieving consistent, smooth and even dyeing, especially when dealing with difficult-to-dye fibers or using dispersed dyes on synthetic fabrics such as polyester.

Repair Agent (Dye Carriers)

What it is:

Dye carriers, often called repair agents, are chemicals used to improve the penetration of dyes into fibers. Dye carriers act as solvents to help dyes penetrate the fibers more effectively, especially during low-temperature dyeing processes. They also help fix color inconsistencies or uneven dyeing that may occur during the process. Dye carriers increase the affinity between dyes and fabrics, allowing for a smoother, more even distribution of color.

Why it is essential:

In some fabrics, especially synthetic fabrics, dyes may not easily penetrate the fibers at standard dyeing temperatures. Dye carriers help overcome this problem, ensuring that the dyes are evenly absorbed and achieving color fixes when necessary.

Wash-Off Agents (Soaping Agents)

What is it:

Washing agents or soaping agents are used to remove any excess or unfixed dye from fabrics after dyeing. They help wash away any dye particles that are not chemically bound to the fiber. These agents work by breaking the bond between the unfixed dye and the fabric, allowing the excess dye to be easily removed during the washing process. This step is essential to ensure that the final product does not contain any residual dye, preventing color bleeding or staining during subsequent washings.

Why it is essential:

Soaping agents are essential to ensure color durability and fastness. They prevent fading or bleeding, which can compromise the quality of the final product, especially for products used in high-wear environments.

Conclusion

Dyeing is a critical process in textile manufacturing, and using the right dye auxiliaries can significantly improve the efficiency and quality of the dyeing process. The five major dyeing auxiliaries – sequestering agents, anti-wrinkling agents, dispersing and leveling agents, dye carriers, and soaping agents – work together to improve dye absorption, prevent common dyeing problems, and ensure that the final product meets the desired color, appearance, and quality standards.

At BLUELAKECHEM, we specialize in providing innovative and high-performance textile auxiliaries designed to optimize your dye carriers and dyeing processes. We are committed to providing comprehensive solutions that improve the quality of your fabrics while ensuring cost-effectiveness and process efficiency. If you would like to improve your dyeing process or have any questions about our products, please feel free to contact us for a consultation or request a personalized quote.