Fabric Chemical Testing & Textile Auxiliaries Application

At BLUELAKECHEM, we use rigorous textile testing services to evaluate the actual impact of chemical auxiliaries on fabric performance, ensuring that your products meet market demand and customer expectations.

Fabric Chemical Testing Methods

We focus on testing the effects of textile auxiliaries on fabrics, from physical properties to functional requirements, ensuring the stability and high quality of your fabrics in various usage scenarios.

Fabric Color Test

Use a colorimeter to detect the color value and record the ΔE value (color difference value) to ensure the consistency of the fabric color.

Strength Test

Evaluate fabric tensile and tear strength with bursting strength machine to ensure durability in real-world use.

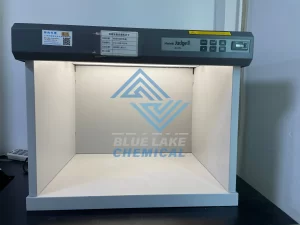

Light Source Color Matching

Evaluate the color difference of the sample under different lighting conditions to ensure the color stability and consistency of the textile.

Sweat Color Fastness Test

Assess fabric color stability against sweat's heat, humidity, acidity, and salt to check for fading or color transfer.

UV Protection Test

Test fabric's ability to block UV rays, ensuring effective sun protection for clothing, hats, and other products.

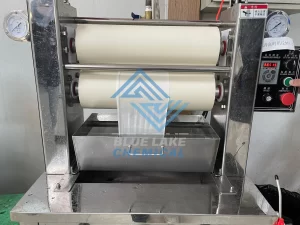

Washfastness Test

Test fabric's color retention after multiple washes to ensure long-lasting color stability.

More Chemical Testing of Textiles

Wetting Capillary Effect Test

Record the rate at which moisture rises in the fabric to test the fabric's wicking performance and moisture absorption capacity.Breathability Test

Test the breathability of textiles to evaluate their applicability in high-intensity sports or outdoor environments.Anti Pilling Test

Use a pilling tester to simulate the friction process, evaluate the fabric's anti-pilling performance, and improve the fabric's durability and comfort.Abrasion Fastness Test

Detect the color transfer of the fabric under friction, divided into two test methods: dry friction and wet friction.Antibacterial Performance Test

Evaluate textiles' ability to inhibit or kill microorganisms such as bacteria and fungi to ensure their antibacterial effect in specific applications.

Our Quality Inspection Process

We provide customized testing solutions based on different testing needs to ensure meet international standards and customer requirements.

Step 1

Establish Material List (BOM)

Create a detailed Bill of Materials (BOM) to ensure all raw materials meet production requirements and environmental standards.

Step 2

Set Environmental Testing Standards

Develop specific testing standards based on environmental regulations to ensure all raw materials and products meet eco-friendly criteria.

Step 3

Pre-Storage Laboratory Testing

Conduct laboratory tests on incoming materials to ensure they meet specifications and quality standards before being stored.

Step 4

Bulk Production

After confirming material quality, proceed with mass production, ensuring that the manufacturing process adheres to quality control requirements.

Step 5

Finished Product Testing

Perform thorough testing on finished products to ensure they meet quality standards and customer requirements.

Step 6

Sample Retention

Retain samples from each batch for traceability, enabling tests on the same batch in case of customer complaints.

Step 7

Start Custom Developing Textile Chemicals NowPackaging and Shipping

Package the finished products to ensure safe transport and delivery, protecting products during the shipping process.

Contact Us Now

Reach out for professional assistance with textile auxiliaries chemicals. Our team is here to help with all your textile needs.

+86-18946995563Complaint Hotline: +86-15766227459Info@gdcxchem.comFactory Address: East of Gucuo Section, Sishen Road, Liangying Town, Chaonan District, Shantou City, Guangdong Province, ChinaOffice Address: Floor 8, Lechao Building, Huangshan Road, Longhu District, Shantou City, Guangdong Province, China