In textile manufacturing, textile pretreatment plays a vital role in preparing the fabric for subsequent treatments such as dyeing, printing and finishing. The process improves the quality and performance of fabrics, ensuring that they meet the specifications required for various applications. In this blog, we will explore the importance of textile pretreatment processes, its methods and its contribution to the overall textile production process.

What is Textile Pretreatment?

Textile pretreatment refers to the chemical or physical treatment process of fabrics before dyeing, printing or finishing. The goal is to remove any impurities present on the fibers, improve the fabric’s wettability, uniformity, dyeability and fastness, and make the fabric easier to dye, print or otherwise finish. Through pretreatment, we can effectively solve various problems that may arise in the production process of textiles.

Core Links of Pretreatment Process

Textile pretreatment processes usually include wetting, scouring, degreasing, bleaching, bio-polishing and other links, each of which has its specific purpose and technical requirements.

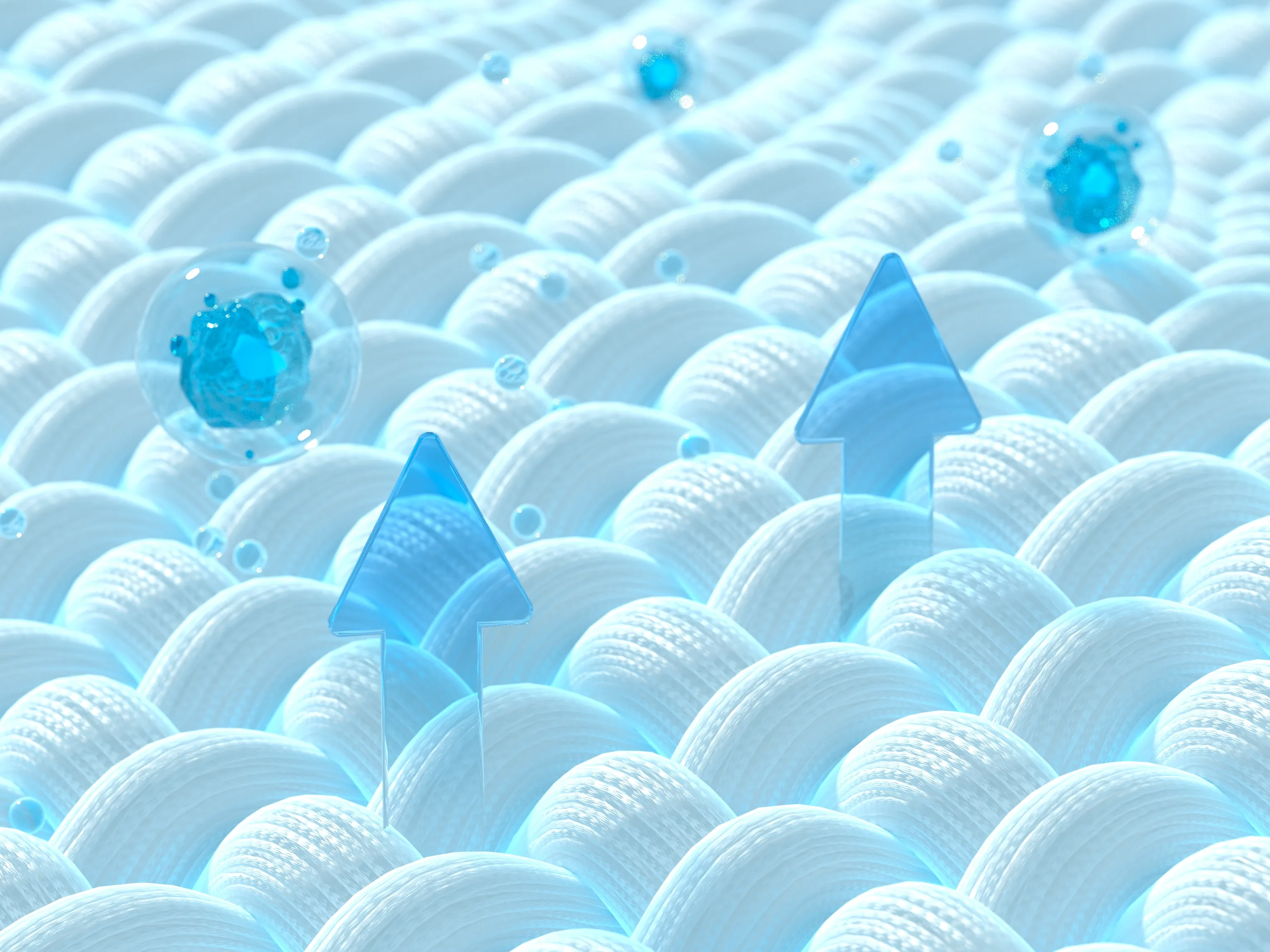

Wetting: Wetting is the first step in many pretreatment processes, allowing the fabric to effectively absorb aqueous solutions. It involves treating the fabric with surfactants to reduce the surface tension and make it easier for water to penetrate the fibers.

Scouring: Scouring is the process of removing natural oils, waxes and other impurities from fabrics, especially natural fibers such as cotton. Scouring helps improve the cleanliness of fabrics and ensures that dyes and finishes can be applied more effectively.

Degreasing: Removing sizing from fabrics, and any fatty substances, oils and waxes that may be present, restores the fibers to their original softness and absorbency. Degreasing agents help prepare fabrics, ensuring better dye absorption and a more consistent finish.

Bleaching: Bleaching fabrics and removing any color impurities that may be present. Bleaching is particularly important when producing fabrics that require high brightness or dyeing processes that require a clean, uniform base.

Biopolishing: Using biological enzymes to break down specific compounds in fabrics, such as pectin in cotton or protein in wool. It makes the fabric feel smoother and look more lustrous, and is suitable for high-end fabrics and fabrics that require advanced finishes (such as silk or fine cotton).

Key Benefits of Textile Pretreatment

Improving Dyeing Performance Textile pretreatment enhances dye absorption by removing impurities from the fabric, resulting in a more uniform and vivid color effect.

- Enhance Fabric Softness

The textile pretreatment process also involves processes that improve the feel of the fabric. Softeners and surface treatments can make fabrics more comfortable and nicer to the touch. - Improve Durability

Pretreated fabrics are better able to withstand subsequent processes, thereby increasing the longevity of the finished product. This is particularly important for textiles used in harsh environments or products that require high durability, such as upholstery or industrial fabrics. - Improve Printability

For printed fabrics, the pretreatment of textiles ensures that the fibers are clean and open, making them more receptive to ink or dye. This process improves the quality and clarity of the printed pattern.

Textile Pretreatment Auxiliaries: A Critical Element in the Process

Pretreatment auxiliaries are essential chemicals that aid the pretreatment process by improving the handling properties of the fabric and ensuring optimal results. These include a range of textile auxiliaries such as wetting agents, dispersing agents and bleaching agents. The right choice of pretreatment auxiliaries ensures better performance during dyeing, printing and finishing, and reduces processing time and costs.

Our Textile Pretreatment Solutions

At Bluelakechem, we specialize in providing high-quality textile pretreatment chemicals and pretreatment auxiliaries to meet the specific needs of your manufacturing process. Our products are designed to enhance fabric quality, improve dyeing performance and optimize the entire pretreatment process. With 30 years of expertise, we provide customized solutions to maximize fabric performance. Whether you are looking for surfactants, softeners or enzyme treatments, we have the right products to enhance your textile pretreatment process.

If you want to know more about fabric processing and textile pretreatment solutions, please contact us today for more information and receive a free sample of our textile pretreatment chemicals!